Vibration damping

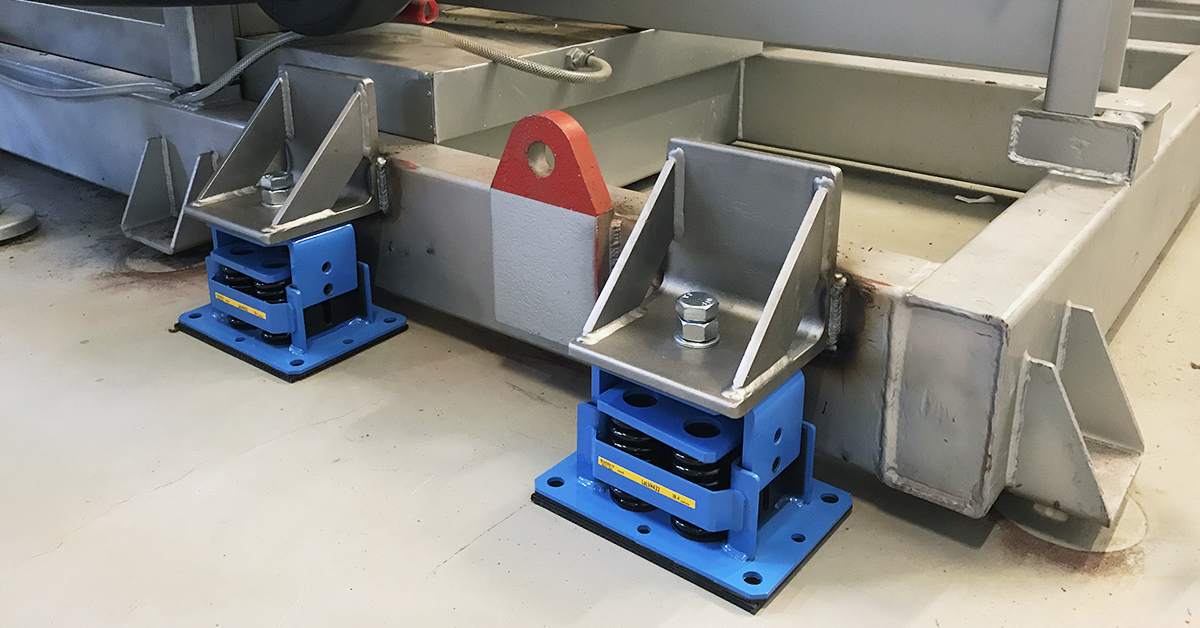

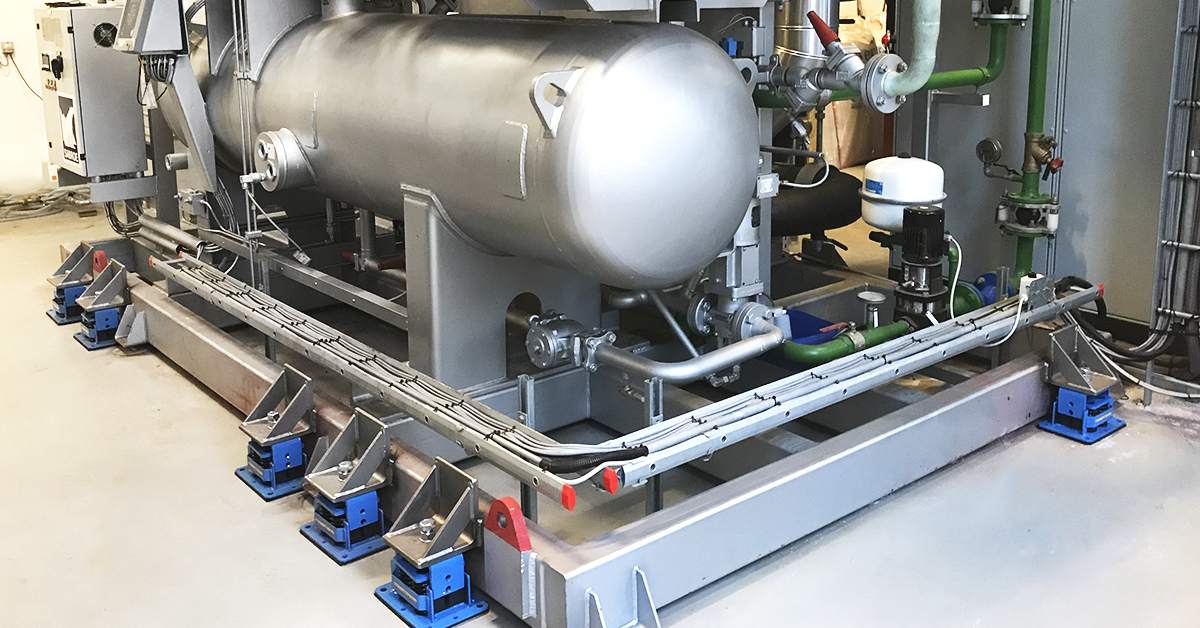

The requirements for quiet machines and their surroundings continue to become stricter, but a large number of noise and vibration problems in industrial facilities, offices, homes, vehicles, etc. can be remedied by using vibration damping. For example, unbalanced machinery generates vibrations which are transferred to the underlay and from there further propagate as noise (structure noise).

Recommendations for vibration damping

The purpose of vibration isolation is to reduce vibrations transmitted from the machine to the underlay. A corrctly sized anti-vibration mount can reduce vibrations by more than 90 %, but never by 100 %. (90 % isolation means that only 10 % of the vibratory force is transferred).

Machine noise and vibrations

Noise pollution from production machines can be a significant challenge in many industries and work environments. Among other things, due to productivity, health and well-being, it is important to implement effective solutions for noise and vibration reduction.

Vibration measurement and calculation

Simultaneous measurement of noise and vibration can help determine which machines are annoying and which are not. The noise may be due to a combination of the machine's high sound output, low sound absorption around the machine and poor acoustic insulation in the building.

Frequently asked questions about vibration damping

Find answers to the most frequently asked questions about vibration damping for industry or housing associations, including vibration damping of washing machines and dryers in laundry rooms.