Recommendations for vibration damping

Vibrations and structure noise

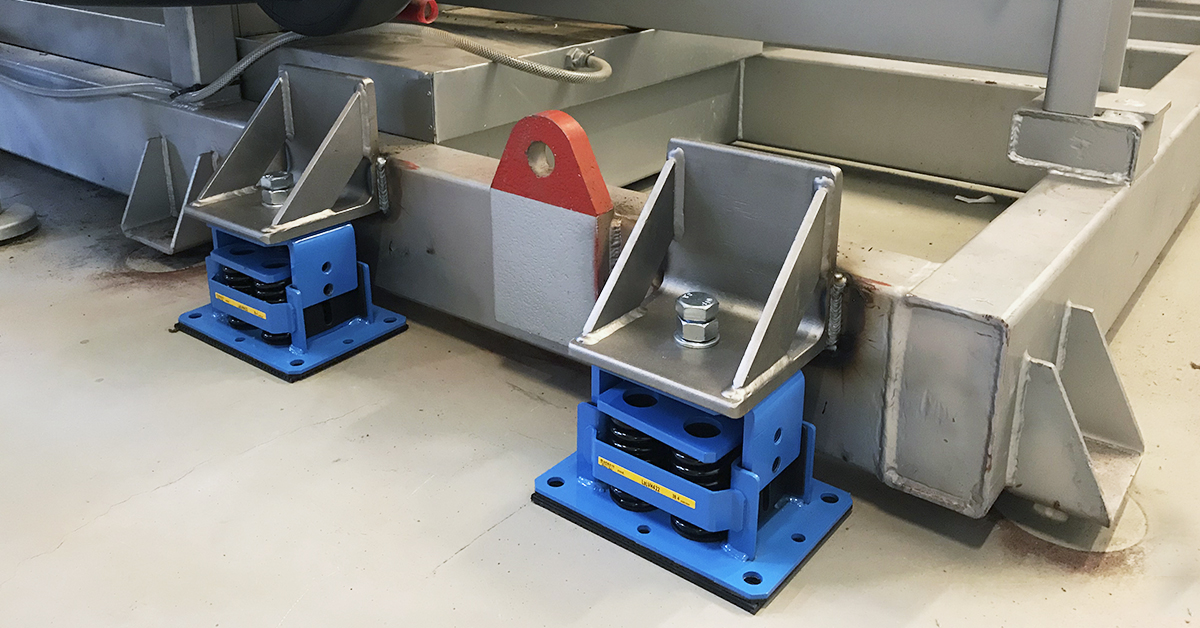

The requirements for quiet machines and their surroundings continue to become stricter, but a large number of noise and vibration problems in industrial facilities, offices, homes, vehicles, etc. can be remedied by using anti-vibration mounts. Unbalanced machinery generates vibrations which are transferred to the underlay and from there further propagate as noise (structure noise).

Reduce vibrations by more than 90 %

The purpose of vibration isolation is to reduce vibrations transmitted from the machine to the underlay. A correctly sized anti-vibration mount can reduce vibrations by more than 90 %, but never by 100 %. (90 % isolation means that only 10 % of the vibratory force is transferred).

A machine set up on anti-vibration mounts constitutes an oscillating system with at least one natural frequency. If the disturbing frequency (e.g. the machine’s rpm) falls with the natural frequency, vibrations are amplified. The best isolation is achieved when the disturbing frequency is considerably higher than the natural frequency. Most machines are difficult to counterbalance completely, and imbalances can, for example, be solved through vibration isolation. When a number of assumptions are made about the oscillating system, the dimensioning procedure is relatively simple.

Types of rubber

Rubber is produced in a variety of types which have specific properties.

IACs own brand of anti-vibration mounts are normally made from one of the types of rubber shown on the next page, al-though other types of rubber are available:

Read more about types of rubber and quality

Material properties

Hardness

In order to best utilise the rubber’s properties, IAC own brand of anti-vibration mounts are made in different hardnesses. Since the rubber cannot be compressed, spring action can only be achieved when the rubber is under a load and can “bulge” out. The deflection of the rubber is determined by its size, shape and hardness. The hardness of the rubber indicates its resistance to deformation under pressure. Rubber can withstand large compressive loads with a deflection of approximately 20 % of the unloaded height.

Cross-load, or “shear” can normally take up to 20 % of the pressure load. The rubber should ideally not be subjected to tensile loads, as these significantly reduce the rubber’s service life.

Read more about dimensioning rules

Read more about types of rubber and quality